fat test for lv panels | iec 61439 routine test fat test for lv panels Siemens offers multiple options for factory acceptance testing of select low- and medium-voltage products tailored to fit your needs. Choose a shipping service that suit your needs with FedEx. Whether you need a courier for next day delivery, if it’s heavy or lightweight – you’ll find a solution for your business. Login to your account or learn more about how to become a better shipper, printing offers, or get inspiration for your small business.

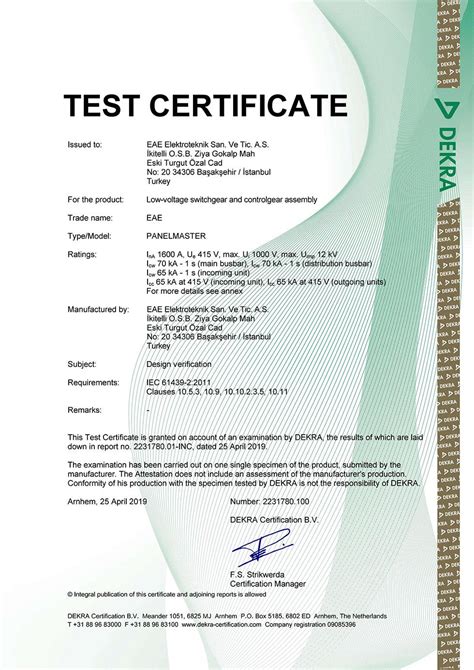

0 · type test certificate for panel

1 · machine fat checklist

2 · iec 61439 testing requirements

3 · iec 61439 routine test

4 · generator factory acceptance test checklist

5 · factory acceptance test report sample

6 · factory acceptance test procedure template

7 · factory acceptance test fat

Rem Villiers. 2.94K subscribers. Like. 2.3K views 4 years ago #FFXIV #gaming #mmorpg. Final Fantasy XIV - Job Quest "Succession of Steel" Red Mage Class at level 80 in Mor Dhona.

Learn the necessary Factory Acceptance Testing (FAT) processes for Low Voltage (LV) switchboard. Learn about inspection procedures, testing methodologies, and compliance checks to guarantee safety, functionality, and .The aim of this documentation is to outline the FAT procedure of Low Voltage Main Switchboard. A) Visual Inspection Test B) Insulation Test C) High Voltage Injection Test D) Primary Current .

This document outlines the factory acceptance test (FAT) procedure for low voltage switchboards. The FAT includes (1) a visual inspection, (2) insulation testing, (3) high voltage injection testing, (4) primary current injection testing to .The aim of this documentation is to outline the FAT procedure of Low Voltage Main Switchboard. Visual Inspection Test. Insulation Test. High Voltage Injection Test. D) Primary Current .

Siemens offers multiple options for factory acceptance testing of select low- and medium-voltage products tailored to fit your needs. Major inspection should be scheduled for power plant shutdowns and concentrate for low voltage switchboards on identifying contact wear, correct operation of interlocks, correct overload settings and fuse sizes, signs of .A Level 1 - FAT is the most basic level of equipment/system testing conducted at the OEM. This is often the level of acceptance test for equipment that is similar to other equipment in the plant . The FAT is a comprehensive test that is performed on low-voltage switchgear to verify that the equipment meets the requirements of the customer's order and the applicable specifications and.

The document outlines the factory acceptance test (FAT) procedure for low voltage switchboards. It details the visual inspection, insulation, high voltage injection, primary current injection, secondary current injection, and metering .

Factory Acceptance Test (FAT) procedure. Visual Inspection Test. Visual inspection with customer will be carried out on the LV switchboard to: Check the layout of fitted components. Check the over all dimension of switchboard, size of busbars, cables and earthing conductors and location of feeder entry point.

Learn the necessary Factory Acceptance Testing (FAT) processes for Low Voltage (LV) switchboard. Learn about inspection procedures, testing methodologies, and compliance checks to guarantee safety, functionality, and dependability prior to installation.The aim of this documentation is to outline the FAT procedure of Low Voltage Main Switchboard. A) Visual Inspection Test B) Insulation Test C) High Voltage Injection Test D) Primary Current Injection Test E) Metering Current Transformer Polarity Test F) Secondary Current Injection Test 1.2 Working LocationThis document outlines the factory acceptance test (FAT) procedure for low voltage switchboards. The FAT includes (1) a visual inspection, (2) insulation testing, (3) high voltage injection testing, (4) primary current injection testing to check protection relays and CT polarities/ratios, (5) secondary current injection testing of protection .The aim of this documentation is to outline the FAT procedure of Low Voltage Main Switchboard. Visual Inspection Test. Insulation Test. High Voltage Injection Test. D) Primary Current Injection Test. E) Metering Current Transformer Polarity Test. F) Secondary Current Injection Test.

Siemens offers multiple options for factory acceptance testing of select low- and medium-voltage products tailored to fit your needs. Major inspection should be scheduled for power plant shutdowns and concentrate for low voltage switchboards on identifying contact wear, correct operation of interlocks, correct overload settings and fuse sizes, signs of overheating, and undue dirt or corrosion.A Level 1 - FAT is the most basic level of equipment/system testing conducted at the OEM. This is often the level of acceptance test for equipment that is similar to other equipment in the plant or for equipment that has simple to moderate upgrades and/or modifications. The FAT is a comprehensive test that is performed on low-voltage switchgear to verify that the equipment meets the requirements of the customer's order and the applicable specifications and.

The document outlines the factory acceptance test (FAT) procedure for low voltage switchboards. It details the visual inspection, insulation, high voltage injection, primary current injection, secondary current injection, and metering current transformer polarity tests to be performed. Factory Acceptance Test (FAT) procedure. Visual Inspection Test. Visual inspection with customer will be carried out on the LV switchboard to: Check the layout of fitted components. Check the over all dimension of switchboard, size of busbars, cables and earthing conductors and location of feeder entry point. Learn the necessary Factory Acceptance Testing (FAT) processes for Low Voltage (LV) switchboard. Learn about inspection procedures, testing methodologies, and compliance checks to guarantee safety, functionality, and dependability prior to installation.

The aim of this documentation is to outline the FAT procedure of Low Voltage Main Switchboard. A) Visual Inspection Test B) Insulation Test C) High Voltage Injection Test D) Primary Current Injection Test E) Metering Current Transformer Polarity Test F) Secondary Current Injection Test 1.2 Working LocationThis document outlines the factory acceptance test (FAT) procedure for low voltage switchboards. The FAT includes (1) a visual inspection, (2) insulation testing, (3) high voltage injection testing, (4) primary current injection testing to check protection relays and CT polarities/ratios, (5) secondary current injection testing of protection .The aim of this documentation is to outline the FAT procedure of Low Voltage Main Switchboard. Visual Inspection Test. Insulation Test. High Voltage Injection Test. D) Primary Current Injection Test. E) Metering Current Transformer Polarity Test. F) Secondary Current Injection Test.

Siemens offers multiple options for factory acceptance testing of select low- and medium-voltage products tailored to fit your needs. Major inspection should be scheduled for power plant shutdowns and concentrate for low voltage switchboards on identifying contact wear, correct operation of interlocks, correct overload settings and fuse sizes, signs of overheating, and undue dirt or corrosion.

type test certificate for panel

machine fat checklist

A Level 1 - FAT is the most basic level of equipment/system testing conducted at the OEM. This is often the level of acceptance test for equipment that is similar to other equipment in the plant or for equipment that has simple to moderate upgrades and/or modifications.

The FAT is a comprehensive test that is performed on low-voltage switchgear to verify that the equipment meets the requirements of the customer's order and the applicable specifications and.

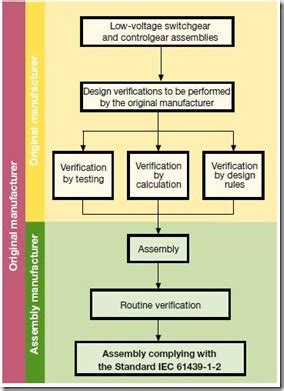

iec 61439 testing requirements

iec 61439 routine test

generator factory acceptance test checklist

45 talking about this

fat test for lv panels|iec 61439 routine test